Showing posts with label power. Show all posts

Showing posts with label power. Show all posts

Did, Energy, Facts, power, Solar, teach, you. know, Yourself

Unknown

9:43 AM

The consumption of non-renewable sources like oil, gas and coal is increasing at an alarming rate. The time has finally come to look after some other renewable sources of energy i.e. solar, wind and geothermal energy. Although many countries have started utilizing solar energy extensively but still they have to go a long way to exploit this energy to fulfil their daily demand for energy. Here are few facts on solar energy that can help you assess the potential of solar energy to meet global requirements.

1. Solar has Incredible Potential

If we add the amount of solar energy that is absorbed by the Earth’s atmosphere, land and oceans every year, we end up with approximately 3,850,000 EJ (exajoules or 10^18 joules).

To put it in more understandable terms, this amount of energy is equivalent to:

2.7 million earthquakes of the same size as the Tohoku earthquake in Japan (2011). 40 000 times the total energy consumption in the United States 8 000 times the total consumption in the whole world. About 40% of the energy that is required to heat the entire volume of water we have on Earth by 1°Celsius

Unfortunately, harnessing all this energy is not achievable. Here’s an overview that illustrates the potential of solar power more realistically:

2. Is Solar Power Green?

Let me get one thing clear: Solar power is certainly greener than conventional ways of harnessing energy sources such as fossil fuels and coal.

On the other hand, there are issues regarding manufacturing of the solar panels, as well as disposal and recycling of byproducts. Where does the solar panel end up when it is no longer usable? (Most solar panels for home only have a warranty of 25 years).

Emissions of greenhouse gases do take place during the manufacturing. Dangerous climate gases such as nitrogen trifluoride and sulfur hexafluoride are both on the list. These literally have many thousand times the impact on global warming as an equal amount of carbon dioxide would.

3. Solar Powered Aircrafts!

Yes, it’s true. NASA has been working on a series of solar powered unmanned aircraft since the 1980’s. Pathfinder, Pathfinder Plus and Helios Prototype, is the result of NASA’s efforts to use solar power for long duration high altitude flights.

4. Solar Energy is Nuclear Fusion

Nuclear power is a term we use to describe ways to harness energy through nuclear fission and fusion processes. Conventional nuclear reactors rely on the fission of uranium atoms to produce heat, which we use to generate electricity. Nuclear fission processes releases vast amounts of heat, but is still far from the potential of fusion, the exact same phenomena that powers the Sun (as well as other stars).

Scientists are now working on what can be described as “the holy energy grail of energy”, or how to harness nuclear fusion, and they have been doing so for the last 70 years.

If we are able to tame this power before we reach a century of scientific efforts is uncertain. What is certain is that once we reach this milestone, the way we harness energy will be revolutionized. We are no longer dependent on resources when it comes to energy. Terms like renewable and sustainability will become meaningless. We will move into a new paradigm where knowledge = energy.

Heavy hydrogen (also known as deuterium) that is extracted from not more than 1L seawater, can with nuclear fusion generate energy equivalent to what we find in 300 L petrol.

5. The Sun is Dying

You probably know that solar energy is considered a renewable energy source. The reason for this is that the electromagnetic radiation emitted from the Sun (also known as sunlight) will be around for us to harness, and will not disappear anytime soon:

According to astrophysics, the Sun was born about 4.57 billion years ago and has another 6-7 billion years before it becomes a white dwarf (a planetary stage where nuclear fuel in the star is exhausted).

Fortunately you don’t have to worry about this. When the hydrogen reserves on the Sun are depleted, it will expand into a red giant, and will likely swallowing the Earth. Luckily we have another 5 billion years before this will happen!

costs, electric, Energy, estimation, Hydro, hydroelectricity, management, micro, plants, power, Principle, project, quebec, whey

1. Starting costs

2. Construction and installation costs

3. Operation phase costs

The third category encompasses management, operation and maintenance costs related to the operation phase of the power plant. An estimation of these costs is necessary in order to calculate the financial projections of the project.

In August 2010, the PSP Hydro team of GIZ in Rwanda completed the study ‘Privatisation of the Management of Existing Micro Hydro Power Plants: Feasibility analysis and strategy’. For this study, financial analyses of 18 publicly funded MHPPs had to be carried out. In order to do this, the PSP Hydro team created a model for the estimation of the operation phase costs for these plants, most of which were still under construction. This model (Management_cost_estimation_model.xls) is presented in this article.

The basic principal of the spreadsheet is that operational costs are directly related to the size as well as to the costs of categories 1 and 2. For example, the number of personnel will be bigger for bigger plants and the insurance cost will be directly related to the value (or cost) of the installed assets. The model is valid for MHPPs between 100 kW and 3 MW.

The required information is:

- Generation capacity (kW)

- Investment on civil works (RwF)

- Investment on electromechanical system (RwF)

- Investment on distribution system (RwF)

- Investment on office equipment (RwF)

- Cost of starting and other project costs (RwF)

The outputs (in RwF), for each of which an individual estimation is made, are:

The coincidence with Fichtner (2009) and MARGE (2010) suggests that

the model developed by PSP Hydro provides adequate estimations, at least

for the study on privatisation for which it was created. However, as

soon as the MHPPs co-financed by PSP Hydro are operational and real data

is available, the model should be improved. This is a useful tool for

feasibility analysis of MHPPs in Rwanda and could easily be adapted to

other developing countries.

Unknown

10:56 PM

The feasibility analysis of a micro-hydro power plant (MHPP) requires the estimation of three categories of costs:

1. Starting costs

2. Construction and installation costs

3. Operation phase costs

The third category encompasses management, operation and maintenance costs related to the operation phase of the power plant. An estimation of these costs is necessary in order to calculate the financial projections of the project.

In August 2010, the PSP Hydro team of GIZ in Rwanda completed the study ‘Privatisation of the Management of Existing Micro Hydro Power Plants: Feasibility analysis and strategy’. For this study, financial analyses of 18 publicly funded MHPPs had to be carried out. In order to do this, the PSP Hydro team created a model for the estimation of the operation phase costs for these plants, most of which were still under construction. This model (Management_cost_estimation_model.xls) is presented in this article.

Estimation model

Initially, the PSP Hydro team planned to collect information of existing MHPPs in operation in Rwanda in order to create a benchmark database from which estimate the costs of the new ones. To do this, the PSP Hydro team carried out consultations with 5 companies that were responsible for 6 hydropower plants, between 50 kW and 2 MW, in 2010. Unfortunately, the companies could only provide very poor records of their operational expenditures. Therefore, PSP Hydro had to change its strategy. To compensate the lack of real data, PSP Hydro drew in its own expertise to develop the spreadsheet for the calculation of operation phase costs for MHPPs that is in attachment.The basic principal of the spreadsheet is that operational costs are directly related to the size as well as to the costs of categories 1 and 2. For example, the number of personnel will be bigger for bigger plants and the insurance cost will be directly related to the value (or cost) of the installed assets. The model is valid for MHPPs between 100 kW and 3 MW.

The required information is:

- Generation capacity (kW)

- Investment on civil works (RwF)

- Investment on electromechanical system (RwF)

- Investment on distribution system (RwF)

- Investment on office equipment (RwF)

- Cost of starting and other project costs (RwF)

The outputs (in RwF), for each of which an individual estimation is made, are:

- Personnel

- Maintenance contract for power plant

- Insurance

- Electricity and water bills

- Office stationary

- Consumables and spares (excluded office)

- Communication and promotional actions

- Transport

- Office rent

- Local taxes

- Environmental management

Reliability of the model

This is a simplified model but the obtained results are comparable to those presented in previous studies in Rwanda:- Fichtner (2009), ‘Actualisation Study of the Electricity Masterplan, Section 6, Economic & Financial Assessment’; DECON, December 2009. (See Tables 4-7, page 4-12)

- MARGE (2010), ‘Elaboration d’un plan stratégique national de maintenance des équipements de production et de distribution de l’énergie renouvelable’, BTC, July 2010. (See presentation of Robert J. van der Plas on ‘Maintenance Strategy for RET in Rwanda’ delivered on July 7th 2010 within the framework of MARGE’s study)

Recommendations

The coincidence with Fichtner (2009) and MARGE (2010) suggests that

the model developed by PSP Hydro provides adequate estimations, at least

for the study on privatisation for which it was created. However, as

soon as the MHPPs co-financed by PSP Hydro are operational and real data

is available, the model should be improved. This is a useful tool for

feasibility analysis of MHPPs in Rwanda and could easily be adapted to

other developing countries.

electric, Energy, Hydro, hydroelectricity, Maintenance, Operation, plants, power, Principle, project, quebec, whey

Ongoing operation, maintenance, and surveillance (OMS) are required to keep a plant running smoothly. However, OMS should not be considered only after building a micro hydro facility. It should be considered in choosing a site, designing the facility and when looking for financing. Sites that are remote or have poor access will have greater servicing costs. Facility design can greatly influence ongoing OMS costs including surveillance requirements and replacement and repair costs. Consideration should also be given to the availability of spare parts and the possible purchase of spare parts in advance. In financing the project the annual OMS costs need to be factored into the overall project cash flow. Thus, OMS should be thought of continually throughout the development of the micro hydro project.

The ease with which maintenance can be performed should also be considered during the design phase of a micro hydro facility. For example, equipment that requires regular maintenance should be located in a place that is easily accessible, and not located in a confined space. Also, if any equipment may need to be removed for maintenance during its lifetime, the means of achieving such a task should be considered. For instance, if any part of the generator needs to be removed for replacement, repairs, or upgrades - is there an economical way of doing it? Is there a hoist or crane capable of moving all the pieces of the generator? Can the roof of the building be removed easily for external crane access? By meticulously thinking through all the possible OMS scenarios that may occur, a lot of time and money can be saved over the life of the project.

Unknown

10:55 PM

Introduction

Micro hydro operation and maintenance (O+M) procedures must be planned and put into action in the initial stages of any scheme to prevent breakdowns and reduced power outputs. The failure to use O+M procedures will result in financial problems and loss of confidence in the value of micro-hydro. The design engineer, the equipment installers and the users of the scheme, all have important parts to play in the O+M of micro-hydro schemes.Ongoing operation, maintenance, and surveillance (OMS) are required to keep a plant running smoothly. However, OMS should not be considered only after building a micro hydro facility. It should be considered in choosing a site, designing the facility and when looking for financing. Sites that are remote or have poor access will have greater servicing costs. Facility design can greatly influence ongoing OMS costs including surveillance requirements and replacement and repair costs. Consideration should also be given to the availability of spare parts and the possible purchase of spare parts in advance. In financing the project the annual OMS costs need to be factored into the overall project cash flow. Thus, OMS should be thought of continually throughout the development of the micro hydro project.

Design considerations

It is essential that the long-term OMS costs be considered during the design of a micro hydro facility. For instance, it may be initially cheaper to buy and use uncoated steel pipe rather than a pipe coated for corrosion protection. Once the maintenance costs (the cost of replacing or field coating steel pipes to deal with corrosion), operating costs (increased friction and reduced energy with uncoated pipe), and expected life span are considered it may be cheaper to purchase coated steel pipe. This type of lifetime and reliability analysis should be considered carefully in all aspects of the design – it could save a lot of time and money.The ease with which maintenance can be performed should also be considered during the design phase of a micro hydro facility. For example, equipment that requires regular maintenance should be located in a place that is easily accessible, and not located in a confined space. Also, if any equipment may need to be removed for maintenance during its lifetime, the means of achieving such a task should be considered. For instance, if any part of the generator needs to be removed for replacement, repairs, or upgrades - is there an economical way of doing it? Is there a hoist or crane capable of moving all the pieces of the generator? Can the roof of the building be removed easily for external crane access? By meticulously thinking through all the possible OMS scenarios that may occur, a lot of time and money can be saved over the life of the project.

Managing OMS

Even for the smallest micro hydro installations, a plan that ensures the consistent operation, maintenance, and surveillance of the facility is useful, if not necessary. To accomplish consistency in OMS, plans and procedures should be developed. These plans are typically located in the following documents:- OMS Manual - The OMS Manual contains the operating instructions for the plant. It is written in a language that the operators can easily understand. OMS Manuals ensure consistent error-free operation of the plant.

- Equipment Manuals - Manufacturers usually provide Equipment Manuals for most equipment (i.e. turbines, hoists, pumps, switches, etc.). The availability and organization of equipment manuals greatly help OMS efficiency. A great deal of time and money can be spent on trying to find out how to do the necessary OMS, when the actual OMS may take little time or money to complete.

- Facility Drawings and Design Information - Make sure to keep the proper design information and drawings for all aspects of the plant that are uniquely designed. This information can make future repairs and modifications much easier.

- Maintenance Schedule - A Maintenance Schedule outlines when and what maintenance should be done. A schedule should be made according to a specific plant’s equipment OMS needs. It could consist of a checklist that must be signed by a supervisor or a worker once the maintenance has been completed. It could be a schedule developed using specially designed scheduling software.

- Log Books and OMS Records - Log Books record what OMS has been completed, and what has happened in the day-today operations of the plant. This can help trouble shoot problems regarding the facility’s OMS down the road. If any major work is completed that greatly changes the facility’s design or operation, a record should be kept for future reference. Over time, new operators will be hired and they can benefit from the recorded experience of their predecessors in operating the plants.

Components, electric, Energy, Hydro, hydroelectricity, plants, power, Principle, project, quebec, whey

A turbine converts the energy in falling water into shaft power. There are various types of turbine which can

be categorized in one of several ways. The choice of turbine will

depend mainly on the pressure head available and the design flow for the

proposed hydropower installation. As shown in table 2 below, turbines

are broadly divided into three groups; high, medium and low head, and

into two categories: impulse and reaction.

The difference between impulse and reaction can be explained simply by stating that the impulse turbines convert the kinetic energy of a jet of water in air into movement by striking turbine buckets or blades - there is no pressure reduction as the water pressure is atmospheric on both sides of the impeller. The blades of a reaction turbine, on the other hand, are totally immersed in the flow of water, and the angular as well as linear momentum of the water is converted into shaft power - the pressure of water leaving the runner is reduced to atmospheric or lower.

For Further Information, click here.

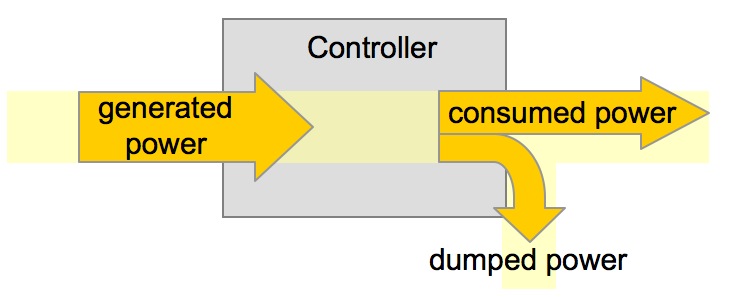

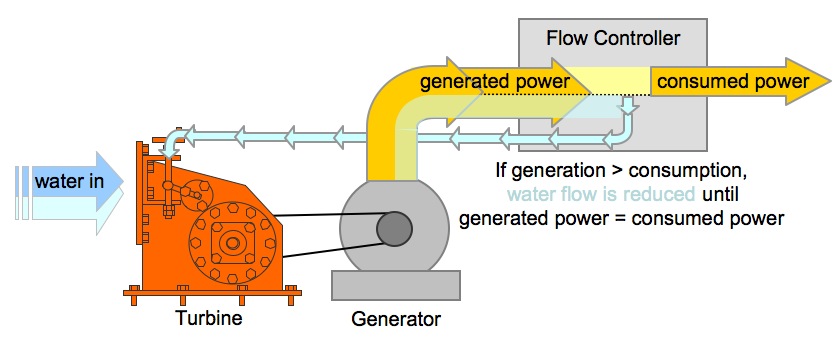

A Load- or Flow- controller ensures that the power output does not exceed the power demand and power output is stable (e.g. 230V, 50 Hz).

Water turbines, like petrol or diesel engines, will vary in speed as load is applied or relieved. Although not such a great problem with machinery which uses direct shaft power, this speed variation will seriously affect frequency and voltage output from a generator.

Traditionally, hydraulic or mechanical speed governors altered flow as the load varied. Nowadays usually electronic load controller (ELC) are used. These prevent speed variations by continuously adding or subtracting an artificial load (load controller). In that in effect, the turbine is working permanently under full load and the ELC diverts excess energy into a dump load, mostly a heater. The traditional kind of equalizing power in and output by controlling the flow is usually also automatised (flow control). Thereby the ELC steers a valve which regulates the amount of water inflowing.

In case of more power demand than supply the controller cuts off single users (clusters) in order to keep voltage and frequency constant for the others (first and second class connections). Load or flow controller are placed between generator output and the consumer line. <span lang="DE" style="font-size: 11pt; color: black; font-family: tahoma" />

For small micro or pico hydropower sites it's sometimes not easy to find the right controller. There is a lower price limit of several 100 USD even for only 1 or 2 kW power. In such cases there may be thought of manual control.

Regarding intelligent load management: Dr Nigel Smith, Dr Philip Taylor and Tim Matthews

Manual flow control

In very small schemes often all power for lighting and TV is used constantly. Then energy consumption barely alters or does only at certain times. In such cases it can be even practical to train an operator who open / closes a valve manually to stabilise the Voltage. This allows to disclaim a controller, which saves costs and potentially flaws.

It is very important to ensure a high plant factor if the scheme is to be cost effective and this should be taken into account during the planning stage. Many schemes use a 'dump' load (in conjunction with an electronic load controller - see below), which is effectively a low priority energy demand that can accept surplus energy when an excess is produced e.g. water heating, storage heaters or storage cookers.

Unknown

10:53 PM

Turbine types

Turbine Runner |

Head

pressure | ||

| High | Medium | Low | |

| Impulse | Pelton

Turgo Multi-jet Pelton |

Crossflow

Turgo Multi-jet Pelton |

Crossflow |

| Reaction | Francis

Pump-as-turbine (PAT) |

Propeller

Kaplan |

|

The difference between impulse and reaction can be explained simply by stating that the impulse turbines convert the kinetic energy of a jet of water in air into movement by striking turbine buckets or blades - there is no pressure reduction as the water pressure is atmospheric on both sides of the impeller. The blades of a reaction turbine, on the other hand, are totally immersed in the flow of water, and the angular as well as linear momentum of the water is converted into shaft power - the pressure of water leaving the runner is reduced to atmospheric or lower.

For Further Information, click here.

Generators

Established producers of hydro generators

MarelliInduction motor as generator

Controller:

Function principlesA Load- or Flow- controller ensures that the power output does not exceed the power demand and power output is stable (e.g. 230V, 50 Hz).

Water turbines, like petrol or diesel engines, will vary in speed as load is applied or relieved. Although not such a great problem with machinery which uses direct shaft power, this speed variation will seriously affect frequency and voltage output from a generator.

Traditionally, hydraulic or mechanical speed governors altered flow as the load varied. Nowadays usually electronic load controller (ELC) are used. These prevent speed variations by continuously adding or subtracting an artificial load (load controller). In that in effect, the turbine is working permanently under full load and the ELC diverts excess energy into a dump load, mostly a heater. The traditional kind of equalizing power in and output by controlling the flow is usually also automatised (flow control). Thereby the ELC steers a valve which regulates the amount of water inflowing.

In case of more power demand than supply the controller cuts off single users (clusters) in order to keep voltage and frequency constant for the others (first and second class connections). Load or flow controller are placed between generator output and the consumer line. <span lang="DE" style="font-size: 11pt; color: black; font-family: tahoma" />

Controller Types

Fluctuating energy demand requires a mechanism which either regulates the water input into the turbine (= flow control) or by diverting excess energy from the consumer connection (= ballast load).For small micro or pico hydropower sites it's sometimes not easy to find the right controller. There is a lower price limit of several 100 USD even for only 1 or 2 kW power. In such cases there may be thought of manual control.

Load control:

The electric load controller (ELC) keeps outgoing Voltage and Frequency stable. Therefore the load on the generator has to be kept stable. The controller adds and subtracts an artificial load (heater) in a way to neutralise the fluctuations on the consumer side.Ballast load

If energy demand is temporarily low the excess energy is dumped. It's converted into heat by some heat elements either in water or air. To increase an mhp's overall efficiency such excess power could be utilised as well. Therefore some storage technology would be required. Battery charging, freezers, water pumping or heat storage may be options. (see also discussionRegarding intelligent load management: Dr Nigel Smith, Dr Philip Taylor and Tim Matthews

Flow control

regulates the amount of water into the turbine in order to match power output and power demand. Nowadays flow control is done mostly via electronics, which steer a valveManual flow control

In very small schemes often all power for lighting and TV is used constantly. Then energy consumption barely alters or does only at certain times. In such cases it can be even practical to train an operator who open / closes a valve manually to stabilise the Voltage. This allows to disclaim a controller, which saves costs and potentially flaws.

Load factor

The load factor is the amount of power used divided by the amount of power that is available if the turbine were to be used continuously. Unlike technologies relying on costly fuel sources, the 'fuel' for hydropower generation is free and therefore the plant becomes more cost effective if run for a high percentage of the time. If the turbine is only used for domestic lighting in the evenings then the plant factor will be very low. If the turbine provides power for rural industry during the day, meets domestic demand during the evening, and maybe pumps water for irrigation in the evening, then the plant factor will be high.It is very important to ensure a high plant factor if the scheme is to be cost effective and this should be taken into account during the planning stage. Many schemes use a 'dump' load (in conjunction with an electronic load controller - see below), which is effectively a low priority energy demand that can accept surplus energy when an excess is produced e.g. water heating, storage heaters or storage cookers.

Classification, electric, Energy, Hydro, hydroelectricity, plants, power, Principle, project, quebec, whey

For the United Nations Industrial Development Organization (UNIDO) and the European Small Hydropower Association (ESHA) and the International Association for Small Hydro a capacity of up to 10 MW total is becoming the generally accepted norm for small hydropower plants (SHP). In China, it can refer to capacities of up to 25 MW, in India up to 15 MW and in Sweden small means up to 1.5 MW, in Canada 'small' can refer to upper limit capacities of between 20 and 25 MW, and in the United States 'small' can mean 30 MW.

The German Federal Ministry for Environment, Nature Conservation and Nuclear Safety mentioned that a SHP is < 1 MW, everything above is a large hydro electric plant and usually comes along with a large dam. The International Commission on Large Dams (ICOLD) defines a large dam as a dam with a height of 15 m or more from the foundation. If dams are between 5-15 m high and have a reservoir volume of more than 3 million m3, they are also classified as large dams. Using this definition, there are over 45 000 large dams around the world.

Small hydro can be further subdivided into mini, micro and pico:

There is no binding definition how Mini hydropower output is to be classified. Rules for communication avoiding misunderstandings: Generally the terms can be used "downwards compatible". Pico- is also Mini- but not visa versa. Specific terms (Pico, Family) should be used only if they are required to indicate specifics. The spectrum needs higher diversification as smaller it becomes as there are certain differences in technique, usage, applicability and the grade of of ability to replicate them.

Comments:

Large hydropower developments involve large dams and huge water storage reservoirs. They are typically grid connected supplying large grids. Preference for large hydro is on the decline due to the high investment costs, long payback periods and huge environmental impacts (losses of arable land, forced migration, diseases and damage to biodiversity). Many social and environmental impacts are related to the impoundment and existence of a reservoir, and therefore are greater for 'large hydro' plants with reservoir.

Small hydropower stations are typically run-of-the-river. They combine the advantages of hydropower with those of decentralised power generation, without the disadvantages of large scale installations. Advantages include: low distribution costs, no/low environmental costs as with large hydro, low maintenance and local implementation and management. Power generated with small hydro station can be used for agro-processing, local lighting, water pumps and small businesses[1].

The constructions and integration into local environments of Small Hydro Power (SHP) schemes typically takes less time and effort compared to large hydropower plants. For this reason, the deployment of SHPs is increasing in many parts of the world, especially in remote areas where other energy sources are not viable or are not economically attractive.

However, larger facilities will tend to have lower costs on a USD/kW basis due to economies of scale, even if that tendency will only hold on average. Moreover, one large-scale hydropower project of 2,000 MW located in a remote area of one river basin might have fewer negative impacts than the cumulative impacts of four hundred 5 MW hydropower projects in many river basins (see also Negative Environmental Impacts). For that reason, even the cumulative relative environmental and social impacts of large versus small hydropower development remain unclear, and context dependent. General concepts like ‘small’ or ‘large hydro’ are not technically or scientifically rigorous indicators of impacts, economics or characteristics. Hydropower projects cover a continuum in scale, and it may be more useful to evaluate a hydropower project on its sustainability or economic performance, thus setting out more realistic indicators[2].

By Facility Type

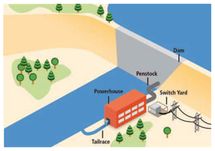

Hydropower plants can be classified in three categories according to

operation and type of flow (see figure a-c). a) Run-of-river (RoR),

b) storage (reservoir) and

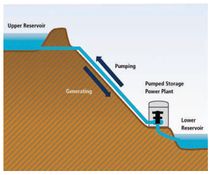

c) pumped storage HPPs

In addition, there is a fourth category (d) called in-stream technology, which is a young and less-developed technology.

Storage HPPs require high dams and big storage areas to be flooded. Such is usually the case in big infrastructure projects including the known environmental impacts. Small and micro hydropower usually avoids those but utilizes water that runs of a river.

Pumped storage HPPs work as energy buffer and do not produce net energy.

a) Run-of-River Hydropower Plant

b) Hydropower Plant with Reservoir

c) Pump Storage Hydropower Plant

d) In-stream Hydropower Scheme

Text and Figures of this article are mainly taken from the Chapter 5 of the IPCC Special Report on Renewable Energy Sources and Climate Change Mitigation (2011). Prepared by Working Group III of the Intergovernmental Panel on Climate Change [O. Edenhofer, R. Pichs-Madruga, Y. Sokona, K. Seyboth, P. Matschoss, S. Kadner, T. Zwickel, P. Eickemeier, G. Hansen, S. Schlömer, C. von Stechow (eds)]. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, 1075 pp.

Unknown

10:50 PM

By Size

Hydropower installations can be classified by size of power output, although the power output is only an approximate diversion between different classes. There is no international consensus for setting the size threshold between small and large hydropower.For the United Nations Industrial Development Organization (UNIDO) and the European Small Hydropower Association (ESHA) and the International Association for Small Hydro a capacity of up to 10 MW total is becoming the generally accepted norm for small hydropower plants (SHP). In China, it can refer to capacities of up to 25 MW, in India up to 15 MW and in Sweden small means up to 1.5 MW, in Canada 'small' can refer to upper limit capacities of between 20 and 25 MW, and in the United States 'small' can mean 30 MW.

The German Federal Ministry for Environment, Nature Conservation and Nuclear Safety mentioned that a SHP is < 1 MW, everything above is a large hydro electric plant and usually comes along with a large dam. The International Commission on Large Dams (ICOLD) defines a large dam as a dam with a height of 15 m or more from the foundation. If dams are between 5-15 m high and have a reservoir volume of more than 3 million m3, they are also classified as large dams. Using this definition, there are over 45 000 large dams around the world.

Small hydro can be further subdivided into mini, micro and pico:

|

< 1 MW | grid connected | special know how required |

|

< 100 kW | partially grid con. | professional know how required |

|

< 10 kW | island grids | small series units produced locally; professional equipment available |

|

< ~1 kW | single households/clusters | often locally handmade solutions; professional equipment available |

There is no binding definition how Mini hydropower output is to be classified. Rules for communication avoiding misunderstandings: Generally the terms can be used "downwards compatible". Pico- is also Mini- but not visa versa. Specific terms (Pico, Family) should be used only if they are required to indicate specifics. The spectrum needs higher diversification as smaller it becomes as there are certain differences in technique, usage, applicability and the grade of of ability to replicate them.

Comments:

- all installations require "special" knowhow

- there are "over the counter" pico turbines available for "self installation"

- Micro hydro is perhaps the most mature of the modern small-scale energy supply technologies used in developing countries. There are thought to be tens of thousands of plant in the “micro” range operating successfully in China[1], Nepal, Sri Lanka, Pakistan, Vietnam and Peru.

- Historically the term hydropower developed from naming very small units towards nowadays huge dams. Then there where new terms created to separate different clusters. All of them are hydropower. What is considered "mini or "micro" may be defined once and forever ... or not. If there are different opinions on this topic you're welcome to open a discussion group on this.

Comments on the debate “small” versus “large” Hydro Power

Classification according to size has led to concepts such as ‘small hydro’ and ‘large hydro’, based on installed capacity measured in MW as the defining criterion. Defining hydropower by size is somewhat arbitrary, as there are no clear relationships between installed capacity and general properties of hydropower or its impacts. Hydropower comes in manifold project types (see Classification By Facility Type) and is a highly site-specific technology, where each project is a tailor-made outcome for a particular location within a given river basin to meet specific needs for energy and water management services.Large hydropower developments involve large dams and huge water storage reservoirs. They are typically grid connected supplying large grids. Preference for large hydro is on the decline due to the high investment costs, long payback periods and huge environmental impacts (losses of arable land, forced migration, diseases and damage to biodiversity). Many social and environmental impacts are related to the impoundment and existence of a reservoir, and therefore are greater for 'large hydro' plants with reservoir.

Small hydropower stations are typically run-of-the-river. They combine the advantages of hydropower with those of decentralised power generation, without the disadvantages of large scale installations. Advantages include: low distribution costs, no/low environmental costs as with large hydro, low maintenance and local implementation and management. Power generated with small hydro station can be used for agro-processing, local lighting, water pumps and small businesses[1].

The constructions and integration into local environments of Small Hydro Power (SHP) schemes typically takes less time and effort compared to large hydropower plants. For this reason, the deployment of SHPs is increasing in many parts of the world, especially in remote areas where other energy sources are not viable or are not economically attractive.

However, larger facilities will tend to have lower costs on a USD/kW basis due to economies of scale, even if that tendency will only hold on average. Moreover, one large-scale hydropower project of 2,000 MW located in a remote area of one river basin might have fewer negative impacts than the cumulative impacts of four hundred 5 MW hydropower projects in many river basins (see also Negative Environmental Impacts). For that reason, even the cumulative relative environmental and social impacts of large versus small hydropower development remain unclear, and context dependent. General concepts like ‘small’ or ‘large hydro’ are not technically or scientifically rigorous indicators of impacts, economics or characteristics. Hydropower projects cover a continuum in scale, and it may be more useful to evaluate a hydropower project on its sustainability or economic performance, thus setting out more realistic indicators[2].

By Facility Type

Hydropower plants can be classified in three categories according to

operation and type of flow (see figure a-c). a) Run-of-river (RoR),b) storage (reservoir) and

c) pumped storage HPPs

In addition, there is a fourth category (d) called in-stream technology, which is a young and less-developed technology.

Storage HPPs require high dams and big storage areas to be flooded. Such is usually the case in big infrastructure projects including the known environmental impacts. Small and micro hydropower usually avoids those but utilizes water that runs of a river.

Pumped storage HPPs work as energy buffer and do not produce net energy.

a) Run-of-River Hydropower Plant

|

|

|

b) Hydropower Plant with Reservoir

|

c) Pump Storage Hydropower Plant

|

d) In-stream Hydropower Scheme

| Space for a figure |

|

Text and Figures of this article are mainly taken from the Chapter 5 of the IPCC Special Report on Renewable Energy Sources and Climate Change Mitigation (2011). Prepared by Working Group III of the Intergovernmental Panel on Climate Change [O. Edenhofer, R. Pichs-Madruga, Y. Sokona, K. Seyboth, P. Matschoss, S. Kadner, T. Zwickel, P. Eickemeier, G. Hansen, S. Schlömer, C. von Stechow (eds)]. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, 1075 pp.

electric, Energy, Flow, Head, Hydro, hydroelectricity, Measuring, plants, power, Principle, project, quebec, whey

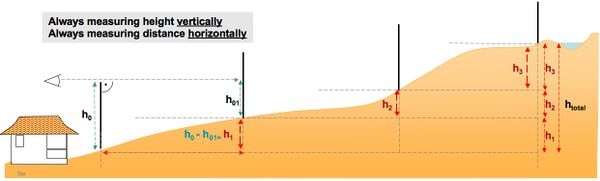

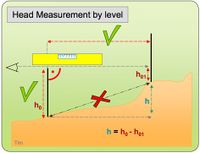

The first step to judge a sites hydropower potential is to measure/estimate head and flow.

Head (the vertical distance between the intake and turbine)

Flow (how much water comes down the stream)

Head is very often exaggerated as is the flow rate, which varies over the year!

Wrong data occurs frequently. Confirmation of existing data is highly recommended!

Head and flow are the two most important facts of a hydro site. This will determine everything about the hydro system—volume of civil constructions, pipeline size, turbine type and power output. Inaccurate measurements result in low efficiency, high cost and scarcity of power.

For sophisticated methods how to inquire a sites feasibility, please check the Manuals section.

"Layman's book: How to develop a Small Hydro Site" may be a good start.

Methods of Head and Flow Measurement without Sophisticated Tools

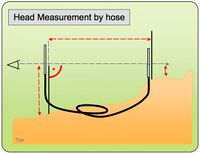

Estimation of height can be done easiest if there is a steep slope (waterfall)by rope. Principle of a step by step head measurement:

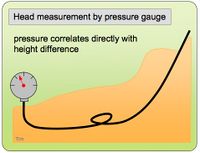

By measuring total height step by step, it's crucial to do the bearing strictly horizontally. Ensure that by using a level or a water filled hose. Widely available are hoses and pressure gauges which allow the easiest method of height measurement. As longer the hose as less steps have to be taken to measure the total head.

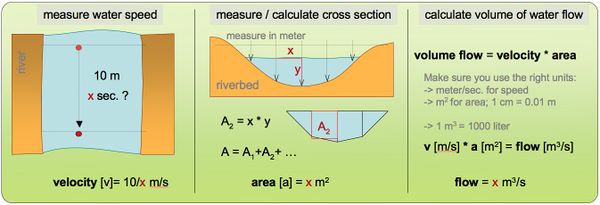

Estimation of flow is very difficult without measurement. A quick and easy way to measure is the floating method

First, measure the waters speed at an steady flowing part of the river. Therefore drop some item and stop the time it needs for a certain distance to float. Second, do a sketch of the rivers cross section by measuring its depth every 20-50 cm so you come up with a grid showing the rivers profile from side to side. With this data its cross sections area can be calculated easily. Finally the flow volume results from (water) speed x (section) area.

Example:

A ball drifts 10 m in 12 s => speed = 10m/12s = 0.12 m/s.

Cross section => A1= 25 cm * 40 cm (0.25 m * 0.4 m) = 0.1 m2 ; A1+A2+ ... = A = 0.5 m2

Flow volume = 0.12 m/s * 0.5 m2 = 0.06 m3/s => 60 l/s

To estimate a sites potential cost its necessary to know additionally:

Pipeline (penstock) length

Electrical transmission line length (from turbine to consumer). As smaller the sites power output as higher the power lines cost share

Number of potential customers

Units and Power Estimations

Power: watts [W] or Kilowatts [kW] 1 kW = 1000W

Flow: 1 m³/s = 1000 l/s

Gross heat: height difference the water "falls down"

Net head: a little smaller than gross head. Gross head deducted by energy loss due to friction in penstock

Potential power ('electric)' is calculated as follows:

Power [W] = Net head [m] x Flow [ l/s] x 9.81 [m/s²] (est. gravity constant) x 0.5 (turbine/generator efficiency)

Potential power is estimated as follows:

Power output [W] = height [m] * flow [l/s] * 5

More accurate estimations take into consideration:

exact net head (intake to powerhouse)

exact flow (constant during the year?)

combined efficiency of turbine and generator (depends on quality, est. 60% = 0.6)

Example:

A 6 m high waterfall has 300 liter/sec => potential power est. : 6 m * 300 l/s * 5 = 9000 W = 9 kW

Unknown

10:49 PM

The first step to judge a sites hydropower potential is to measure/estimate head and flow.

Head (the vertical distance between the intake and turbine)

Flow (how much water comes down the stream)

Head is very often exaggerated as is the flow rate, which varies over the year!

Wrong data occurs frequently. Confirmation of existing data is highly recommended!

Head and flow are the two most important facts of a hydro site. This will determine everything about the hydro system—volume of civil constructions, pipeline size, turbine type and power output. Inaccurate measurements result in low efficiency, high cost and scarcity of power.

For sophisticated methods how to inquire a sites feasibility, please check the Manuals section.

"Layman's book: How to develop a Small Hydro Site" may be a good start.

Methods of Head and Flow Measurement without Sophisticated Tools

Estimation of height can be done easiest if there is a steep slope (waterfall)by rope. Principle of a step by step head measurement:

By measuring total height step by step, it's crucial to do the bearing strictly horizontally. Ensure that by using a level or a water filled hose. Widely available are hoses and pressure gauges which allow the easiest method of height measurement. As longer the hose as less steps have to be taken to measure the total head.

Estimation of flow is very difficult without measurement. A quick and easy way to measure is the floating method

First, measure the waters speed at an steady flowing part of the river. Therefore drop some item and stop the time it needs for a certain distance to float. Second, do a sketch of the rivers cross section by measuring its depth every 20-50 cm so you come up with a grid showing the rivers profile from side to side. With this data its cross sections area can be calculated easily. Finally the flow volume results from (water) speed x (section) area.

Example:

A ball drifts 10 m in 12 s => speed = 10m/12s = 0.12 m/s.

Cross section => A1= 25 cm * 40 cm (0.25 m * 0.4 m) = 0.1 m2 ; A1+A2+ ... = A = 0.5 m2

Flow volume = 0.12 m/s * 0.5 m2 = 0.06 m3/s => 60 l/s

To estimate a sites potential cost its necessary to know additionally:

Pipeline (penstock) length

Electrical transmission line length (from turbine to consumer). As smaller the sites power output as higher the power lines cost share

Number of potential customers

Units and Power Estimations

Power: watts [W] or Kilowatts [kW] 1 kW = 1000W

Flow: 1 m³/s = 1000 l/s

Gross heat: height difference the water "falls down"

Net head: a little smaller than gross head. Gross head deducted by energy loss due to friction in penstock

Potential power ('electric)' is calculated as follows:

Power [W] = Net head [m] x Flow [ l/s] x 9.81 [m/s²] (est. gravity constant) x 0.5 (turbine/generator efficiency)

Potential power is estimated as follows:

Power output [W] = height [m] * flow [l/s] * 5

More accurate estimations take into consideration:

exact net head (intake to powerhouse)

exact flow (constant during the year?)

combined efficiency of turbine and generator (depends on quality, est. 60% = 0.6)

Example:

A 6 m high waterfall has 300 liter/sec => potential power est. : 6 m * 300 l/s * 5 = 9000 W = 9 kW

electric, Energy, Hydro, hydroelectricity, plants, power, Principle, project, quebec, whey

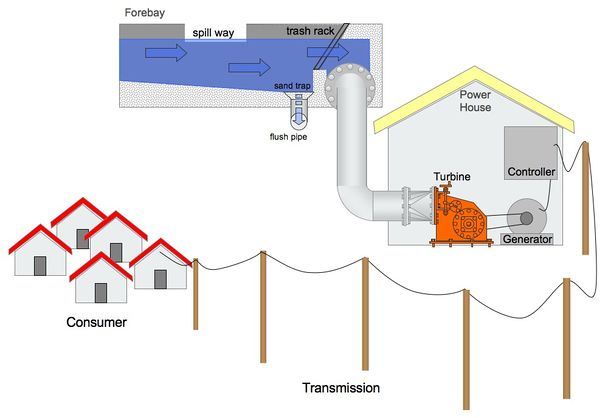

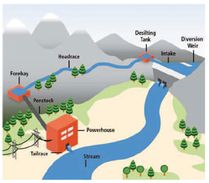

A mass of water moving down a height difference contains energy. This can be harvested. Moving water drives some waterwheel/turbine. This rotation either drives machinery directly (e.g. mill, pump, hammer, thresher, ...) or is coupled with a generator which produces electric power.

Hydropower is probably the first form of automated power production which is not human/animal driven. Moving a grind stone for milling first, developed into the driving of an electrical generator. Next to steam it was for long the main power source for electricity.

Its continual availability does not require any power storage (unlike wind/solar power). It is mainly mechanical hardware. This makes it relative easy to understand and repair-/maintainable. In smaller units its environmental impact becomes neglect-able (see: environmental impact assessment and pros and cons of micro hydropower) .

In order to create electricity from hydropower, two parameters are critical:

Flow; or the minimum amount of water that is constantly available throughout the entire year

Head; the difference in height

These specific conditions limit generalising and standartisation of "how to install hydropower plants". Choosing the right location and planning requires some specific knowledge. With knowledge of water flow and height difference the potential power can be estimated.

Unknown

10:37 PM

A mass of water moving down a height difference contains energy. This can be harvested. Moving water drives some waterwheel/turbine. This rotation either drives machinery directly (e.g. mill, pump, hammer, thresher, ...) or is coupled with a generator which produces electric power.

Hydropower is probably the first form of automated power production which is not human/animal driven. Moving a grind stone for milling first, developed into the driving of an electrical generator. Next to steam it was for long the main power source for electricity.

Its continual availability does not require any power storage (unlike wind/solar power). It is mainly mechanical hardware. This makes it relative easy to understand and repair-/maintainable. In smaller units its environmental impact becomes neglect-able (see: environmental impact assessment and pros and cons of micro hydropower) .

In order to create electricity from hydropower, two parameters are critical:

Flow; or the minimum amount of water that is constantly available throughout the entire year

Head; the difference in height

These specific conditions limit generalising and standartisation of "how to install hydropower plants". Choosing the right location and planning requires some specific knowledge. With knowledge of water flow and height difference the potential power can be estimated.

Energy, green, Panel, Panels, Photovoltaic, power, PV, renewable, Solar

Solar energy is the radiant light and heat from the sun that has been harnessed by humans since ancient times using a range of ever-evolving technologies. Solar radiation along with secondary solar resources account for most of the available renewable energy on earth.

However, only a minuscule fraction of the available solar energy can be used to:

Generate Electricity

Heating and Cooling

Cooking

Water Desalination

Solar Radiation at the Earth's Surface

While the solar radiation incident on the earth's atmosphere is relatively constant, the radiation at the earth's surface varies widely due to:

Atmospheric effects, including absorption and scattering; Local variations in the atmosphere, such as water vapour, clouds, and pollution; Latitude of the location; Season of the year and the time of day.

The above effects have several impacts on the solar radiation received at the earth's surface. These changes include variations in the overall power received, the spectral content of the light and the angle from which light is incident on a surface. In addition, a key change is that the variability of the solar radiation at a particular location increases dramatically. The variability is due to both local effects such as clouds and seasonal variations, as well as other effects such as the length of the day at a particular latitude. Desert regions tend to have lower variations due to local atmospheric phenomena such as clouds. Equatorial regions have low variability between seasons.

Solar Technologies and Techniques

Solar energy technologies refer primarily to the use of solar radiation for practical ends. All other renewable energies other than geothermal derive their energy from energy received from the sun.

Solar technologies are broadly characterized as either passive solar or active solar depending on the way they capture, convert and distribute sunlight. Active solar techniques include the use of photovoltaic modules (also called photovoltaic panels) and solar thermal collectors (with electrical or mechanical equipment) to convert sunlight into useful outputs. Passive solar techniques include orienting a building to the Sun, selecting materials with favorable thermal mass or light dispersing properties, and designing spaces that naturally circulate air.

Active solar technologies increase the supply of energy and are considered supply side technologies, while passive solar technologies reduce the need for alternate resources and are generally considered demand side technologies.

Solar Thermal Technologies

Unknown

10:04 PM

Solar energy is the radiant light and heat from the sun that has been harnessed by humans since ancient times using a range of ever-evolving technologies. Solar radiation along with secondary solar resources account for most of the available renewable energy on earth.

However, only a minuscule fraction of the available solar energy can be used to:

Generate Electricity

Heating and Cooling

Cooking

Water Desalination

Solar Radiation at the Earth's Surface

While the solar radiation incident on the earth's atmosphere is relatively constant, the radiation at the earth's surface varies widely due to:

Atmospheric effects, including absorption and scattering; Local variations in the atmosphere, such as water vapour, clouds, and pollution; Latitude of the location; Season of the year and the time of day.

The above effects have several impacts on the solar radiation received at the earth's surface. These changes include variations in the overall power received, the spectral content of the light and the angle from which light is incident on a surface. In addition, a key change is that the variability of the solar radiation at a particular location increases dramatically. The variability is due to both local effects such as clouds and seasonal variations, as well as other effects such as the length of the day at a particular latitude. Desert regions tend to have lower variations due to local atmospheric phenomena such as clouds. Equatorial regions have low variability between seasons.

Solar Technologies and Techniques

Solar energy technologies refer primarily to the use of solar radiation for practical ends. All other renewable energies other than geothermal derive their energy from energy received from the sun.

Solar technologies are broadly characterized as either passive solar or active solar depending on the way they capture, convert and distribute sunlight. Active solar techniques include the use of photovoltaic modules (also called photovoltaic panels) and solar thermal collectors (with electrical or mechanical equipment) to convert sunlight into useful outputs. Passive solar techniques include orienting a building to the Sun, selecting materials with favorable thermal mass or light dispersing properties, and designing spaces that naturally circulate air.

Active solar technologies increase the supply of energy and are considered supply side technologies, while passive solar technologies reduce the need for alternate resources and are generally considered demand side technologies.

Solar Thermal Technologies

Solar thermal technologies are harnessing solar energy for thermal energy (heat). Solar thermal technologies comprise flat collectors for low- and medium temperatures and high temperature collectors concentrating sunlight using mirrors and lenses.

Solar Electric Technologies

Sunlight can be directly converted into electricity using photovoltaics (PV) and various experimental technologies.

Solar Electric Technologies

Sunlight can be directly converted into electricity using photovoltaics (PV) and various experimental technologies.

Energy, green, Panel, Panels, Photovoltaic, power, PV, renewable, Solar, Technologies, Thermal

Unknown

9:59 PM

Solar thermal technologies involve harnessing solar energy for thermal energy (heat). Solar thermal technologies comprise flat or parabollic collectors (low and medium temperatures and high temperature collectors) concentrating sunlight mainly using mirrors and lenses. Solar heating is the utilisation of solar energy to provide process heat, especially in crop drying, water heating, cooking or space heating and cooling. Advanced designs are also used to generate electricity.

Solar Water Heaters (SWH)

The Technology

Solar water heating (SWH) systems are typically composed of:

- Solar thermal collectors(flat plate or evacuated tube)

- Storage tank

- Circulation loop.

SWH can be either active system or pasive systems:

- Active systems which use pumps to circulate water or a heat transfer fluid. There are the two types of active solar water-heating systems:

- Direct-circulation systems use pumps to circulate pressurized potable water directly through the collectors. These systems are appropriate in areas that do not freeze for long periods and do not have hard or acidic water.

- Indirect-circulation systems pump heat-transfer fluids through collectors. Heat exchangers transfer the heat from the fluid to the potable water. Some indirect systems have "overheat protection," which is a means to protect the collector and the glycol fluid from becoming super-heated when the load is low and the intensity of incoming solar radiation is high.

- Passive systems transfer and circulate heat naturally. Passive solar water heaters rely on gravity and the tendency for water to naturally circulate as it is heated. Because they contain no electrical components, passive systems are generally more reliable, easier to maintain, and possibly have a longer work life than active systems. The two common types of passive systems are:

- Integral-collector storage systems or batch systems consist of a tank that is directly heated by sunlight. These are the oldest and simplest solar water heater designs. They are good for households with significant daytime and evening hot-water needs; but they do not work well in households with predominantly morning draws because they lose most of the collected energy overnight. These solar collectors are suited for areas where temperatures rarely go below freezing.

- Thermosyphon systems are an economical and reliable choice. These systems rely on the natural convection of warm water rising to circulate water through the collectors and to a storage tank located above the collector. As water in the solar collector heats, it becomes lighter and rises naturally into the tank above. Meanwhile, the cooler water flows down the pipes to the bottom of the collector, enhancing the circulation. Indirect Thermosyphon systems use a glycol fluid in the collector loop as a heating medium.

To design, size and select a solar water heating system, the following data is required: daily hot water requirement (litres/day), average insolation (kWh/m2 day), water quality and storage requirements.

Flat Plate Collector

A flat plate is the most common type of solar thermal collector, and is usually used as a solar hot water panel to generate hot water. A weatherproofed, insulated box containing a black metal absorber sheet with built in pipes is placed in the path of sunlight. Solar energy heats up water in the pipes causing it to circulate through the system by natural convection. The water is usually passed to a storage tank located above the collector.

There are many flat-plate collector designs but generally all consist of:

One flat plate collector is designed to be evacuated, to prevent heat loss. The absorber may be made from one of a wide range of materials, including copper, stainless steel, galvanised steel, aluminium and plastics. When choosing an absorber material, it is important to ensure that it is compatible, from the point of view of corrosion, with the other components in the system and with the heat transfer fluid used. The absorber must also be able to withstand the highest temperature that it might reach on a sunny day when no fluid is flowing in the collector (known as the stagnation temperature).

- a flat-plate absorber, which intercepts and absorbs the solar energy,

- a transparent cover that allows solar energy to pass through but reduces heat loss from the absorber,

- a heat-transport fluid (air, antifreeze or water) flowing through tubes to remove heat from the absorber and

- a heat insulating backing.

The fluid passageways of the absorber may consist of tubes bonded to an absorbing plate, or may form an integral part of the absorber. Experience has shown that simple mechanical clamping of tubes to an absorber plate is likely to result in an absorber with a poor efficiency. A good thermal bond, such as a braze, weld or high temperature solder is required for tube and plate designs, in order to ensure good heat transfer from the absorbing surface into the fluid.

Matt black paints are commonly used for absorber surfaces because they are relatively cheap, simple to apply and may be easily repaired. Paints, however, have the disadvantage that they are usually strong emitters of thermal radiation (infrared), and at high temperature this results in significant heat losses from the front of the collector. Heat losses from the collector can be substantially reduced by the use of absorber coatings known as 'selective surfaces'. These surfaces may be applied by electroplating or by dipping a metal absorber in appropriate chemicals to produce a thin semi-conducting film over the surface. The thin film will be transparent to solar radiation but at the same time appear opaque to thermal radiation. However, these surfaces cannot be produced or applied easily.

Flat-plate collectors usually have a transparent cover made of glass or plastic. The cover is required to reduce heat losses from the front of the collector and to protect the absorber and the insulation from the weather. Most covers behave like a greenhouse. They permit solar radiation to pass into the collector, but they absorb the thermal radiation emitted by the hot absorber.

At night it is possible for the collector to lose heat by radiation and the circulation will be in the opposite direction, so the water will cool. This can be overcome by use of a suitable non-return valve. However, there is a danger with solar collectors when used under clear night conditions (e.g. in arid and semi arid regions) that they can actually freeze even when the ambient temperature is above freezing point. In such conditions it may be necessary to have a primary circuit through the collector filled with antifreeze and a separate indirect hot water cylinder where the water from the collector passes through a copper coil to heat the main water supply. This problem will only apply in certain desert regions in the cold season or at high altitudes in the tropics and sub-tropics.

Evacuated Tube Collector

Applications and Efficiency

SWHs are employed in residential, commercial, industrial and public buildings and in industrial processes (drying, pre-heating boiler feed water, cleaning, etc. - see examples for potential on solar thermal applications in industries in India) for the provision of hot water, heat and cooling.

The current commercial market for SWH in the region is predominantly households (high income), hospitals, commercial establishments and tourist facilities.

State of the art solar water heaters incorporate features such as selective surface absorbers, anti-reflective glazing, well-designed collector arrays, efficient storage systems achieving operation efficiencies of the order of 35 to 40%.

A 300-liter system typically suited for family of 4-6 persons will displace up to 1000 kWh of electricity annually.

Capability and Limitations

- Water quality - Solar water heaters require clean, non-hard water for long term operation. Hard or dirty water leads to blockage and corrosion of pipes and storage tanks. Closed circuit systems are recommended where water is hard.

- Installation, Commissioning and Maintenance - Improper installation and commissioning and maintenance of SWHs are the leading causes of system failures.

- High cost of SWH is a major limitation in their uptake. Typical prices for small units range between US$ 1,500 (180 litres) to US$ 2,500 (300 litres).

Costs

Low temperature flat-plate solar collectors typically cost 21 US $ per square metre (0,0021 US $ /cm²). Medium to high temperature collectors generally cost around 200 US $ per square metre. Flat plate collectors are sized at approximately 0,1 square metre (929 cm²) per gallon (3,79 l ) of daily hot water use or 245 cm² per l of hot water. A complete system installed costs around 14 US $/l or 2000 US $ per 150 l.

Maintenance

Solar thermal systems are relatively maintenance free and involve on an occasional basis the checking of the piping for leaks and the cleaning of the collectors. In some regions it may also be necessary to inspect the transfer fluid for freeze protection and to remove the build up of lime scale that chokes the collector and tank recirculating pipes over a period of time.

electric, Energy, green, Panel, Panels, Photovoltaic, power, PV, renewable, Solar, Technologies

Solar energy can be converted directly or indirectly into electricity by the use of the solar electric technologies:

DIRECT: With the use of photovoltaic modules.

INDIRECT: With concentrating solar power.

Photovoltaics (PV) system

Photovoltaics (PV) is the field of technology and research related to the application of solar cells for energy production by converting the solar radiation (sunlight, including sun ultra violet radiation) directly into electricity using the photovoltaic effect.

The PV systems can be grid conected or off grid. Off grid system or stand alone systems are the so called solar home systems (SHS).

In the case of concentrating solar power the solar radiation is concentrated into a small area. This heats up a flud that is used to power a heat engine conected to a generator to produce electricity.

Solar Bottle Bulbs

Solar bottle bulbs were first developed in Brazil and since then has been adopted in different parts of the world.

Read more here....

Unknown

9:56 PM

Solar energy can be converted directly or indirectly into electricity by the use of the solar electric technologies:

DIRECT: With the use of photovoltaic modules.

INDIRECT: With concentrating solar power.

Photovoltaics (PV) system

Photovoltaics (PV) is the field of technology and research related to the application of solar cells for energy production by converting the solar radiation (sunlight, including sun ultra violet radiation) directly into electricity using the photovoltaic effect.

The PV systems can be grid conected or off grid. Off grid system or stand alone systems are the so called solar home systems (SHS).

In the case of concentrating solar power the solar radiation is concentrated into a small area. This heats up a flud that is used to power a heat engine conected to a generator to produce electricity.

Solar Bottle Bulbs

Solar bottle bulbs were first developed in Brazil and since then has been adopted in different parts of the world.

Read more here....

Subscribe to:

Posts (Atom)